Cassette Deck

1981

DEM 599,-

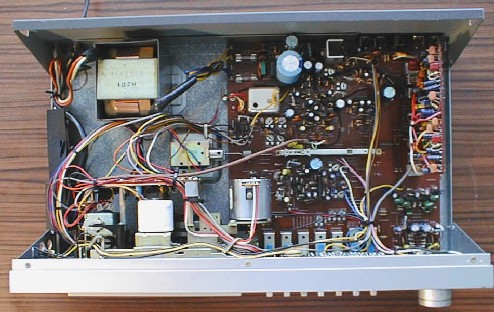

The RC200 was the 'middle choice' of the Silver Series cassette decks, and for some people, it has almost legendary status, since it won many tests in german HiFi magazines like 'Audio' at that time. Compared to the RC100, it is substantially heavier. The main reason for this is the much larger transformer, needed to drive the solenoids and the second motor: the RC200 has a full electronic drive control with the solenoids switching among STOP/PLAY/FF/REW, plus an extra second motor dedicated to the tape reels. Especially the latter significantly reduces the mechanical complexity.

Electronic Drive Control; HighCOM; Dolby-B compatible; Fe/Cr/FeCr/Metal Tape Support; switchable multiplex filter; mechanical tape counter with memory function; 2 Peak-Hold LED displays

Radio/Phono/Tape (DIN); Microphone/Aux (DIN); Line in/out (4xCinch); Headphone (6.3mm)

(taken from the user's manual and from the service instructions. When the service and user manuals gave different numbers, I listed the ones from the service manual.)

| Tape Speed : | 4.75 cm/s +/-1.5% |

| Variation of Speed: | <= +/-0.16% (REC+PLAY) |

| <= +/-0.12% (only PLAY) | |

| Frequency Range: | 30-14000 Hz (Fe2O3) |

| 30-16000 Hz (CrO2) | |

| 30-18000 Hz (FeCr) | |

| 30-18000 Hz (Metal) | |

| Harmonic Distortion: | <= 1% (Fe2O3 and FeCr) |

| <= 3% (CrO2) | |

| <= 2% (Metal) | |

| Reduction of max. High Frequency Level at 10 KHz: | <= 11 dB (Fe2O3) |

| <= 11 dB (FeCr) | |

| <= 12 dB (CrO2) | |

| <= 3 dB (Metal) | |

| S/N Ratio with HIGH COM NR: | 72 dB (Fe2O3) |

| 73 dB (FeCr) | |

| 74 dB (CrO2) | |

| 73 dB (Metal) | |

| Playback Deemphasis: | 3180 µs / 120 µs (Fe2O3) |

| 3180 µs / 120 µs (FeCr) | |

| 3180 µs / 70 µs (CrO2) | |

| 3180 µs / 70 µs (Metal) | |

| Rewind Time: | approx. 80 sec for a C60 tape |

| 100 sec with Cue and Review?? | |

| Erase Damping: | >= 70 dB |

| Erase Frequency: | 85 kHz +/- 1 kHz |

| L/R Channel Damping: | >= 40 dB |

| Input Sensitivity: | 0.4 mV / 7 kOhm (Radio/Micro) |

| 30 mV / 470 kOhm (Aux) | |

| 180 mV / 60 kOhm (Line) | |

| Output Voltage: | 1.1V / 2 kOhm (Radio/Line) |

| 350 mV / 400 Ohm (Headphone) | |

| Multiplex Filter: | 19 kHz Pilot Tone Suppression >= 36 dB |

| Semiconductors: | 16 ICs |

| 45 Transistors | |

| 16 Diodes | |

| 27 LEDs | |

| Mains Voltage: | 220V +/- 10% |

| Mains Frequency: | 50-60 Hz |

| Dimensions: | 435x111x250 mm |

| Weight: | 8.1 kg |

Somewhere during production, Telefunken adopted a so-called 'Soft Switch' add-on circuit for the HighCOM ICs. This has nothing to do with the way the audio signals are switched (this was never done with mechanic relays...), it refers to the way the compander's time constants are changed. The add-on circuit dynamically varies the time constants and reduces the 'pumping' effect known from most compander systems.

Shown are two different RC200 HighCOM modules: on the left, an original module without the add-on and on the right a module with the modifications applied. Telefunken didn't want to redesign the whole module. Instead, the ICs plus the additional components are now located on daughterboards which themselved are soldered into the module like the IC alone before. The interposer boards are oriented vertically, which means that ribbon cables had to be used to make the connections on one side. These cable connections are a bit unreliable, and it may pay to resolder them if you suspect problems in that area.

The most common failure are problems with fast forwarding and/or rewinding the tape. Since the FF/REW mechanics is rather symmetrical, it is common that either both directions work or none. The usual reason is a lack of friction between the rubber wheels and the tape reels. To fix this, first remove the reel motor It is located at the top edge of the mechanics, beween the reels. Remove the front cover and you see a tiny screw that holds the L-shaped metal sheet the motor is fixed to. Getting the motor out is a bit tricky, but it is possible without disassembling anything else. Don't force it!

Now that the motor is out, all rubber wheels are freely accessible. Clean the small wheel attached to the motor's axis, the 'flying wheel' that springs either to the left or right side, depending on the direction, and the plastic wheels on the reel axes themselves. Put the motor in place again. In 3 out of 4 cases, FF and REW work perfectly afterwards. If not, try slightly bending the L-shaped sheet to get more tension into the system.

The second-most common failure are worn-out belts that transfer the right reel's rotations (a) to a rotation sensor and (b) to the tape counter. Early symptoms is a tape counter that gets 'stuck' when it is about to roll over from X00 to (X-1)99: in this moment, the belts aren't capable any more to transfer the increased torque needed for the rollover. I have made attempts with cleaning the belts, but it seems hopeless: get new belts. Their exact type is uncritical, as long as the diameter (45 to 47 mm) is OK. I personally used two identical rectangular belts from Koenig electronic, 47mm diameter.

When an RC200 gets 15+ years old, you could very well expect that the light bulb that illuminates the cassette window is burned out. Very true: From the 6..7 RC200s I own, there are only three with a working bulb. The bulb itself is a very tiny one, without a socket, comparable to a reed contact and soldered onto a small PCB that is glued onto semi-transparent window in the cover. I haven't bothered up to now to look for a replacement, the decks work also well without the illumination ;-)

(taken from Telefunken's 1981-1991 Service Handbook)

| Modules, Sets | |

|---|---|

| HIGHCOM-Module with Softswitch | 349 355 055 |

| Modules, Sets | |

| Logic Board | 339 330 116 |

| ICs, Transistors, Diodes | |

| M54886 IC | 339 575 365 |

| BA6208 IC | 339 575 368 |

| 2SC1815GR Transistor | 339 556 299 |

| Heads, Motors, Transformers | |

| Rec./Playb. Head | 339 350 112 |

| Servo Motor | 339 300 008 |

| Motor without PCB | 339 300 014 |

| Misc. Electrical Parts | |

| Sliding Switch | 339 440 855 |

| Micro Switch | 339 440 139 |

| Switch | 339 440 119 |

| Moving Parts | |

| GA-Lever, complete | 339 755 214 |

| Capstan (Rubber) Roll | 339 755 111 |

| Reel Plate | 339 740 115 |

| Reel Plate, lower Part | 339 744 111 |

| Capstan Roll Lever | 339 755 113 |

| Tape Counter Belt | 339 730 110 |

| Main (flat) Belt | 339 730 111 |

| Misc. Mechanical Parts | |

| Ring for Record Level Knob | 339 230 108 |

| Knob | 339 210 121 |

| Pull-Back Spring | 339 900 118 |

| Spring for intermediate Wheel Lever | 339 900 124 |

| Flywheel Bearing | 339 715 108 |

Adding a remote control input to the RC200, making it controllable via the RP300 pre-amplifier.